The discussion about safety protection usually raises some ears and eyebrows because that means that money is going to be spent. What do you get out of investing in safety equipment and protocols at your fabrication shop or construction site? Well the answer to that is simple, safe workers, on time pilot plant and distillation system project deadlines, and most importantly you get a peace of mind.

The discussion about safety protection usually raises some ears and eyebrows because that means that money is going to be spent. What do you get out of investing in safety equipment and protocols at your fabrication shop or construction site? Well the answer to that is simple, safe workers, on time pilot plant and distillation system project deadlines, and most importantly you get a peace of mind.

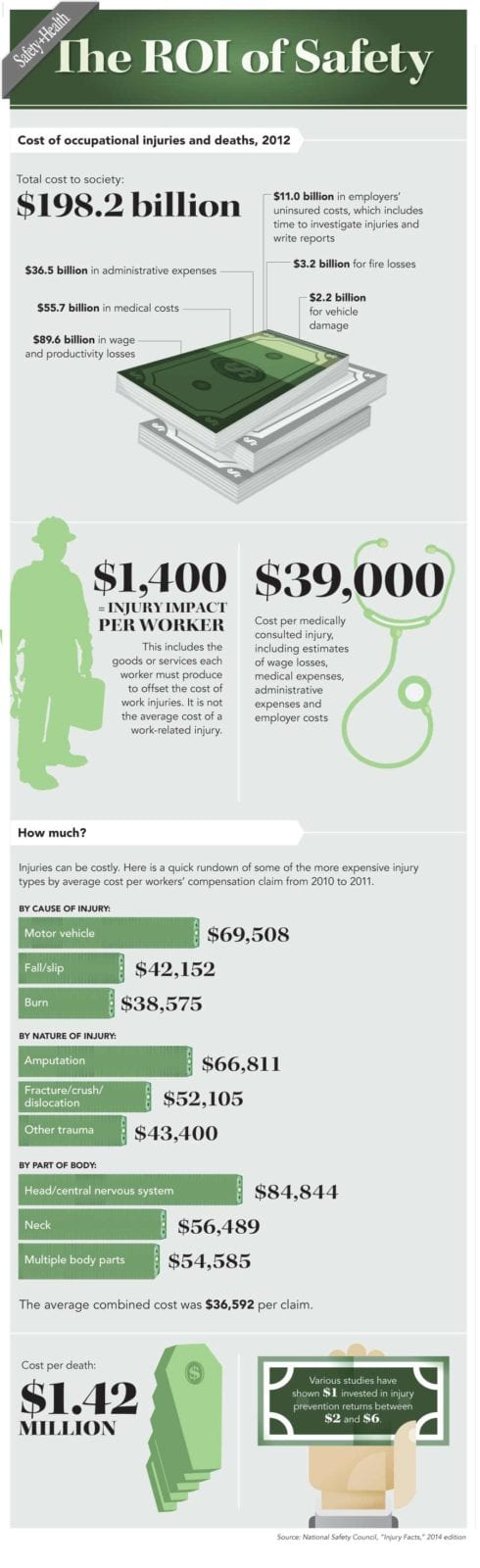

Lets use fall protection as an example. The equipment needed for proper fall protection practices is expensive, no question. That expense increases depending the number of crew members that are working on the pilot plant or distillation tower. But there are serious precautions that need to be known if a company decides to ignore the importance of proper fall protection systems and procedures. Most obviously, a worker could be seriously injured or perhaps even killed if they fall from a certain height. So why take the risk? The time and money spent from a worker being seriously injured far outweighs what it costs to get the necessary equipment to keep your fabricators safe. In fact, according to Rigid Lifeline, here is what it would actually cost if a worker were to fall and be seriously injured (with the average worker’s compensation in the United States averaged out to $29.23 per hour):

- 3 months averages out to $15,199.60

- 6 months averages out to $30,399.20

- 1 year averages out to $60, 798.40

These numbers are just the cost of the worker’s compensation from the accident. In addition to this is a pending OSHA investigation of the incident, which could result in a fine between thousands and hundreds of thousands of dollars. There are other expenses that would come up along the way if an incident were to occur such as administrative costs, litigation and settlement fees and the cost of lost work time.

Here is an infographic from Safety + Health Magazine that shows the average costs of different injuries, including falls. As said by our Quality Assurance & Safety Manager, Paul Kirksey “We want everyone to go home the same way they came to work that day. The best way to do this is by consistent safety practice.” The risk of spending the time and money on safety equipment and protocols is well worth the reward of safe workers, on time projects, and a peace of mind.

Additionally, we can provide a copy of our visitor safety requirements for anyone that visits that EPIC facility and plans to tour our 40,000 sp. foot fabrication shop. Contact EPIC to learn more about our safety regulations when we are fabricating a new pilot plant or distillation system.