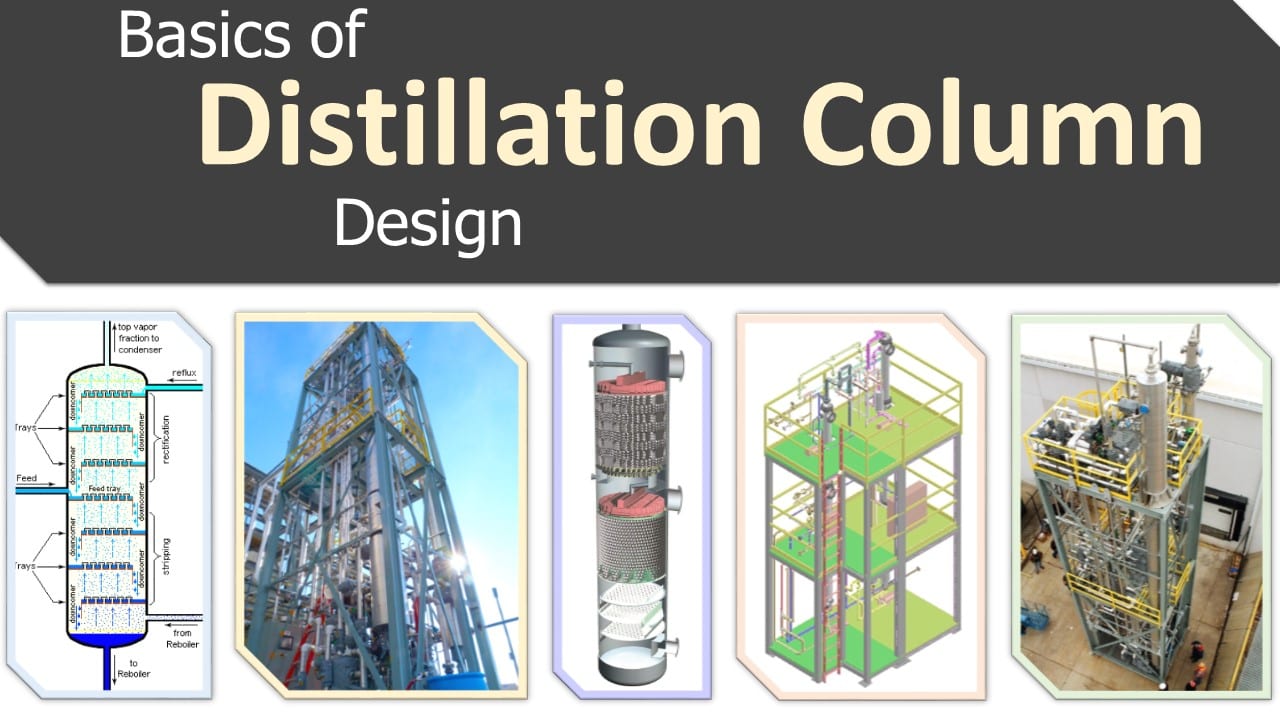

Basic fractional column design concepts and considerations are presented in the presentation below. However, the process begins with a collaborative project development to ensure the model meets your required specifications.

What Distillation Column Designers Need From You

To build an accurate model, engineers must extract your process parameters, including:

Desired system parameters

- The desired heating and cooling mediums

- Desired operating temperature range during heating, separation and cooling

- Desired operating pressure range during heating, separation and cooling

Properties of distillation feed

- Composition

- Solids?

- Non-condensables?

- Azeotropes?

- Feed rate and temperature

Output specifications

- Desired end product specifications

- Chemical composition

- Purity requirements

- Recycle or waste stream

- Acceptable composition?

- Will further processing be required?

What you receive from your column designer

Distillation system scale-up results in the following outputs for you:

1. Complete fractionating column design, including:

- Tower size and width

- Optimal feed location placement

- Minimum number of required trays

- Tray placement and packing selection

2. Mass and energy balances for the finalized distillation column

3. Boiling point curve

4. Utility/support system requirements and basic design

5. Model of distillation column design

If you need expert distillation column design for your process, contact an experienced EPIC engineer today or visit our industrial distillation equipment page for more information on EPIC’s services.